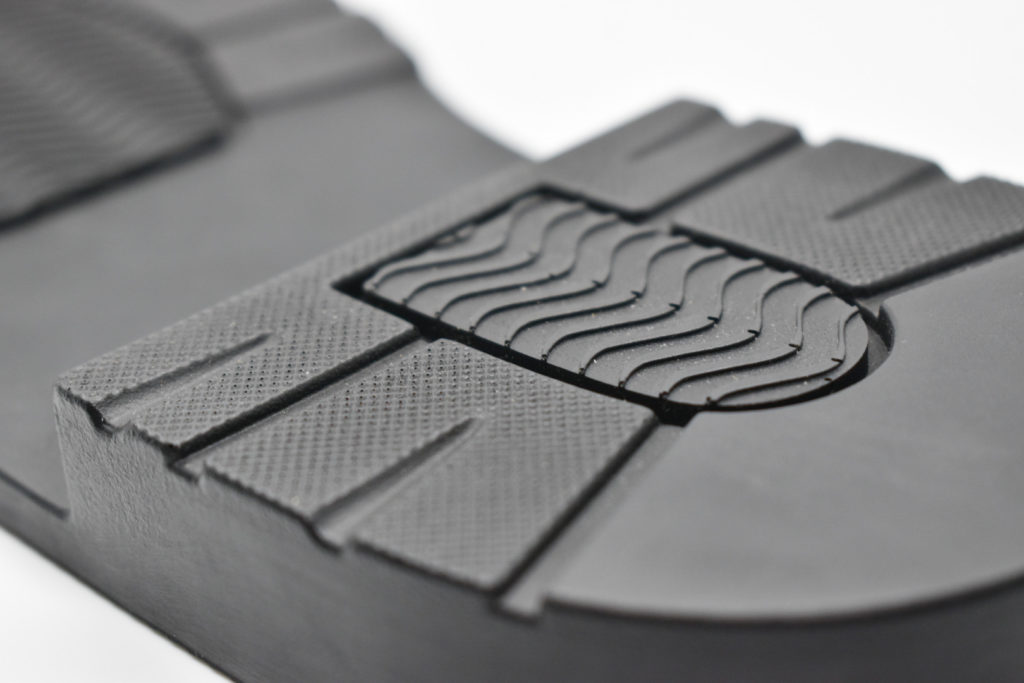

Poly Labs manufactures polyurethane (PU) outsoles for a range of footwear applications. For over 40 years, we’ve molded polyurethane to form both lightweight and durable outsoles.

Polyurethane Outsole Designs

Poly Labs PU outsoles are available in single-density, dual-density and triple-density. These can be over-molded products and customizable with limitless color, stain, finish and traction options.

Examples of polyurethane outsole design features include: standard, slip-resistant, puddle pour, two color, and more.

Dual Density Footwear Outsoles: PU Elastomer

Poly Labs utilizes a high-density PU Elastomer (U-57) as a bottom material for dual density outsoles. Likewise, the elastomer is used for conventional polyurethane molding. It is also used for pads in “puddle pour” molding.

We utilize this same elastomer in other articles in which a durable and solid cast material is necessary. Customers who desire superior flexibility and abrasion properties appreciate the U-57 elastomer material.

PU Elastomer U-57 for Footwear Outsoles Specifications

The qualities for U-57 PU elastomer are as follows:

| Density | 1.0 – 1.1 g/cm³ |

| Hardness, Shore A | 50 – 60 |

| Tensile Strength | 1150 psi |

| Elongation | 650% |

| Die C Tear | 210 pli |

| Ross Flex, cycles to failure @ -20°F | > 30,000 |

| Ross Flex, cycles to failure @ 0°F | > 100,000 |

| Ross Flex, cycles to failure @ 72°F | > 100,000 |

| Abrasion Resistance, Taber, mg loss per 1,000 cycles | < 100 |

| DIN 53516 Abrasion Resistance (mm³ loss) | 128 |

| Oil Swell | |

| ASTM #3 | 1.9 % |

| Fuel B | 29.7 % |

| Fuel F – Diesel | 8.8 % |

| Static Coefficient to Friction, James Test | |

| Dry | 1.1 |

| Wet | 0.94 |

| Static Coefficient to Friction, Mark II | |

| Dry | 1.1 |

| Wet | 0.4 |

| Oily | 0.37 |

| Oily / Wet | 0.16 |

| Linear Shrink | 1.0 % |

Our 40 year history of PU molding allows us to take your concepts from ideas and turn them into reality. PU outsoles are be made-to-order, per the requirements of the customer. Whether you require a double-density design, slip-resistance options, or specialty colors and finishes – you can count on Poly Labs unique ability to meet each of our clients unique requirements, and exceed your expectations.

Poly Labs has a world-class facility in Lewiston, Maine to support our efforts in outsole manufacturing. When you combine technical resources, precision tooling, industry knowledge and expertise – you get Poly Labs, a North American leader in polyurethane outsoles.

For more information on PU Elastomer and polyurethane footwear outsole manufacturing, please contact our sales team.