Poly Labs launched its proprietary Hydrophobic Energy Absorbing Polyurethane (PU) Foam formulas in 2020. It is changing the way helmet and impact protection systems are designed by uniquely combining hydrophobic properties with industry leading impact protection capabilities.

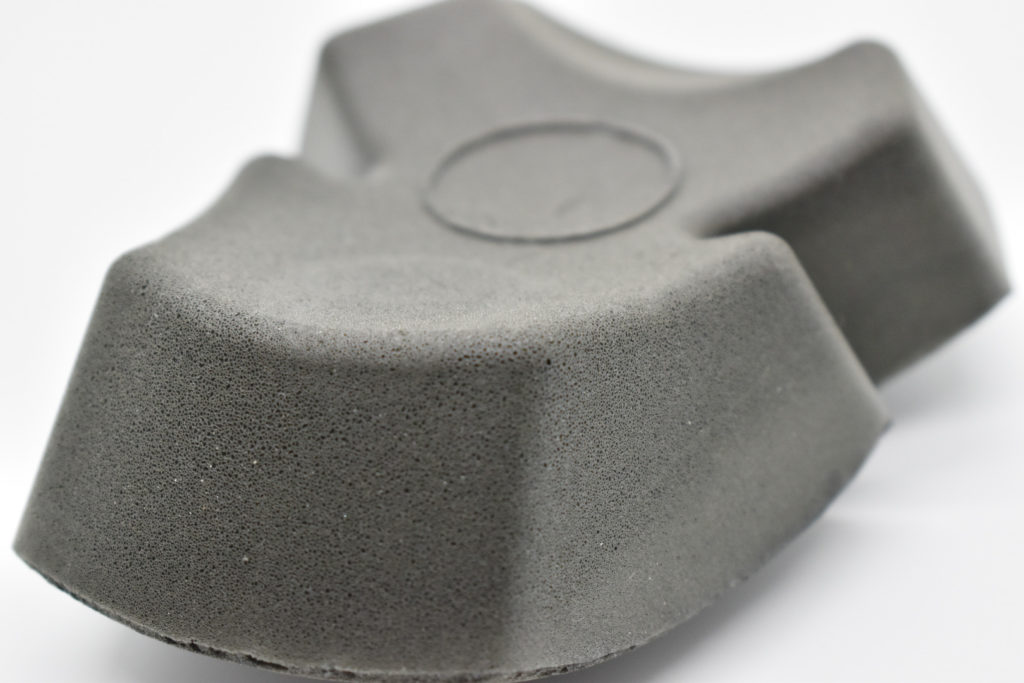

The reason it is considered hydrophobic foam, is because it exhibits low water absorption. This proves extremely useful in applications in which moisture (water, dew, humidity, sweat) is considered a factor. Additionally, this will help to avoid timely and costly secondary processes like bagging. Seen below are a few examples of our EA foam.

With very low rebound upon impaction our U-19 (105) energy absorbing (EA) foam can be molded between 0.15 and 0.20 g/cm³. The compression deflection can be varied to meet specific requirements.

Low-Density U-19 (105) Energy Absorbing Foam

Properties include a low-density energy absorbing foam ideal for combat and athletic impact protection padding. The properties of our U-19 (105) energy absorbing foam are as follows:

| Density | 0.13 to 0.25 g/cm³ |

| Hardness, Shore OO (3 sec) | 70 – 80 |

| Tensile Strength | 190 – 235 psi |

| Elongation | 70 – 95 % |

| Die C Tear | 4.5 – 6.0 pli |

Poly Labs: Hydrophobic EA Foam Experts

The team at Poly Labs works with leading OEM’s of the world’s most critical protection and safety products: military communications gear, audio components, footwear parts, industrial safety tools, medical equipment, and protective padded helmet lining materials for athletes, production workers and firefighters.

Poly Labs decades of technical experience, material knowledge and product development of hydrophobic energy absorbing polyurethane foam sets us apart from other manufacturers.

Our world-class facility in Lewiston, Maine, USA, is home to the state-of-the-art machinery that enables prototype tooling, material selection and poured polyurethane solutions that contribute to the manufacturing of thousands of everyday life products that families, medical professionals, military members, and industrial experts use daily.

For more information about Poly Labs, or to learn more about our hydrophobic energy absorbing foam solutions, please contact our sales team. We look forward to hearing from you!