Poly Labs produces polyurethane bump stops and jounce bumpers for suspension systems, utilized in mountain bikes, military vehicles, race cars, motorcycles and more. Typically, bump stops are made of polyurethane (PU) because of its excellent shock absorbing properties and ability to provide extra cushion caused by impact.

Poly Labs partners with automotive component OEMs, sporting goods equipment manufacturers, suspension & shock system companies, and military combat vehicle experts. We deliver rugged, resilient, and durable polyurethane bump stops, designed specifically for each application.

Furthermore, the Poly Labs team can formulate polyurethane molds and materials depending upon your desired mechanical properties. Whether it is resistance, compression, or tensile strength – we will formulate a component based on your needs. If a specific color, size, diameter or shape is needed, we will manufacture a bump stop, jounce bumper, or other molded polyurethane solution specific to your suspension system.

Applications for Polyurethane Bump Stops

Polyurethane bump stops are installed in a range of vehicle, bicycle, dirt bike, and other off-road equipment applications such as ATVs. They help prevent the inevitable wear and tear of impact on a suspension or shock system. Typically, the applications for polyurethane bump stops include:

- Regular vehicles (sedans)

- Customized off-road vehicles (SUVs)

- Military compact vehicles (AFVs)

- Race cars

- Mountain bikes

- Dirt bikes

- All-terrain vehicles (ATVs)

- Cargo trucks

- Industrial equipment

- Shock systems

Generally, bump stops are an ideal solution for any means of transportation with a suspension system. They are most beneficial in applications in which sudden impact may be a factor.

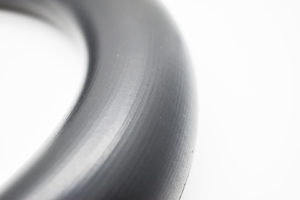

Poly Labs Bump Stop Material: W-02 Polyurethane

Poly Labs formulation W-02 polyurethane is an advanced and resilient material, designed for bump stops and jounce bumpers. This type of PU responds well to impact, and strengthens when compressed. The typical physical and mechanical properties for this formulation are as follows:

| Density: | 0.55 to 0.65 g/cm³ |

| Tensile Strength: | 580 – 720 psi |

| Elongation: | 400 – 450% |

| Die C Tear: | 85 – 115 pli |

| Abrasion Resistance, Taber, mg loss per 1,000 cycles: | < 75 |

| Abrasion Resistance, DIN 53516, mm³ loss: | < 200 |

| Foam Tear: | 20 – 25 pli |

| Ross Flex, cycles to failure @ -20°F: | > 100,000 |

| Oil Swell, ASTM #3: | < 15 % |

| Fuel B: | 37 % |

| Fuel F, Diesel: | 13 % |

| Oil Resistance: | > 250,000 |

| Slip Resistance, James Test | |

| Wet: | 0.89 |

| Dry: | 1.06 |

| Two Hole Stitch Tear: | 288 (lbs. per inch) |

| Hardness, Shore A: | 60 – 75 |

| Linear Shrinkage: | 0.50 % |

Bump Stops for Vehicles

Bump stops are positioned within a vehicle’s suspension system to prevent damage and improve mechanical longevity. Specifically, a bump stop will protect a vehicle’s axles, shocks, tires, fender and other related chassis parts. Additionally, polyurethane bump stops provide an optimal amount of cushioning, which helps prevent other metal parts from touching one another.

Regular & Custom Vehicles

In regular terrain vehicles, bump stops help absorb the shock caused by potholes, speed humps, curb extensions, bumps, or other obstructive objects in the road. Similar to the way they lessen impact on the vehicle’s suspension parts, bump stops also ensure a more safe, smooth, and more comfortable ride for passengers.

In customized off-road vehicles, crawling rocks and traversing uneven trails filled with twists, turns and obstacles is widely popular. Almost always, this warrants the need for bump stops. Replacing custom vehicle parts is expensive, especially in circumstances where damage is preventable. When you encounter a large pothole, bump stops help prevent the chassis of the vehicle and suspension from touching.

Military & Defense Vehicles

For military vehicles, bump stops are critical in reducing the force of impact. Whether it is an IED or rocky terrain, the use of bump stops allows for safer operation of military vehicles. They absorb shock, soften landings, and prevent damage to the suspension systems. In addition, they help reduce other sudden blows (IEDs) a military vehicle may take when travelling.

As a military vehicle climbs unknown terrain ahead, the sudden inclines and drops can compromise the vehicle’s suspension system. In this case, the use of polyurethane bump stops will help if a vehicle needs to climb rocks or overcome rock-filled terrain.

Overall, the use of bump stops in military vehicles allows for better riding and handling behavior. Most importantly, the occupants of a military vehicle are protected from sudden impact or uneasy terrain.

Mountain Bikes

In mountain bikes, bump stops are designed specifically to keep the rider and the bike’s suspension system protected. While off-road mountain bikes traverse mountains, hills, and trails – the suspension system and shocks are at high risk for bottoming out. Bump stops are vital to a mountain bike’s performance, safety, and overall functionality. They help protect against the common culprits encountered while off road: roots, holes, rocks, divots, fallen debris (tree limbs and branches), hard ground, and more.

One of the more substantial impacts a mountain bike can take is in closed circuit racing. Most courses incorporate jumps and rolling hills. If a mountain bike racer overshoots the landing, having bump stops installed helps alleviate any potential incurred damage to shocks, complete suspension system, and most importantly, the rider.

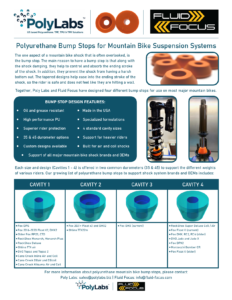

View Mountain Bike Bump Stops Data Sheet

Jounce Bumpers for ATVs & Dirt Bikes

Similar to mountain bikes, jounce bumpers are often installed in shock systems for ATV’s, dirt bikes, and other off-road transportation methods. However, given that higher speed is a factor, the impact force encountered on an all-terrain vehicle is likely much more extreme than that of a mountain bike.

For these suspension systems, a more durable and larger jounce bumper is required. Most custom built race circuits for ATVs and dirt bikes integrate slopes, plummets, obstacles, and barriers within the terrain. In the event of impact or collision caused by any of these factors, a jounce bumper will help reduce the impact and harm to the ATV or dirt bike’s suspension system.

Bump Stops vs. Jounce Bumpers

A bump stop is also known as a jounce bumper. When a vehicle jolts or bounces (“jounces”), a jounce bumper helps alleviate damage to the vehicle. They come in many shapes, sizes, densities, and geometries. So, depending on the application or design, you may hear them referred to as one or the other, interchangeably.

Why use Polyurethane for bump stops and jounce bumpers?

Polyurethane is an ideal material for bump stops and jounce bumpers. It offers exceptional energy absorbing properties, in addition to being an extremely durable material. The PU formulations made by Poly Labs at our Lewiston, Maine, USA facility are geared toward performance, protection and durability. Likewise, our PU materials and components formed at Poly Labs are designed to protect against continuous impact and recurring collision.

Poly Labs: Capabilities

Poly Labs advanced polyurethane and injection molded thermoplastic (TPU, TPE, TPR) formulations offer exceptional performance for demanding applications that require a protected suspension system.

Our ability to research, formulate, and develop polyurethane materials allows us to custom manufacture bump stops and jounce bumpers, specific to the client’s application requirements. Whether it is a suspension system part for a race car, military vehicle, mountain bike, cargo truck, or industrial machine – our team will work with you to identify the best PU component solution.

To learn more about Poly Labs capabilities and products, please contact our customer support team. Our approach is to learn about your application and provide a material or component solution based on your requirement. We look forward to learning about your application!