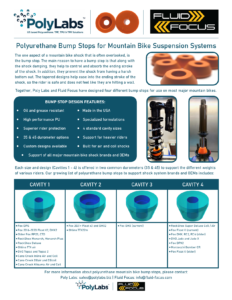

Poly Labs is pleased to announce its development and expanded production capabilities for advanced, race ready, polyurethane mountain bike bump stops through a strategic partnership with mountain bike suspension specialist, Fluid Focus, LLC of San Marcos, CA. Together, Poly Labs and Fluid Focus have designed, manufactured, and tested four different specialized polyurethane bump stops, allowing for use on most mountain bike shock systems.

Through this collaboration, customers will benefit from our combined advanced material research, polyurethane engineering, mold development, high-volume production capabilities, and real-world race tuning. All 100% made in the USA manufacturing takes place in Lewiston, Maine at Poly Labs state-of-the-art polyurethane production facility.

Once designed and manufactured, Fluid Focus then utilizes the bump stops and incorporates them into customers race suspension systems in its world-class suspension tuning, service, and repair factory in San Marcos, CA.

Learn more about Fluid Focus, here.

About Mountain Bike Bump Stops

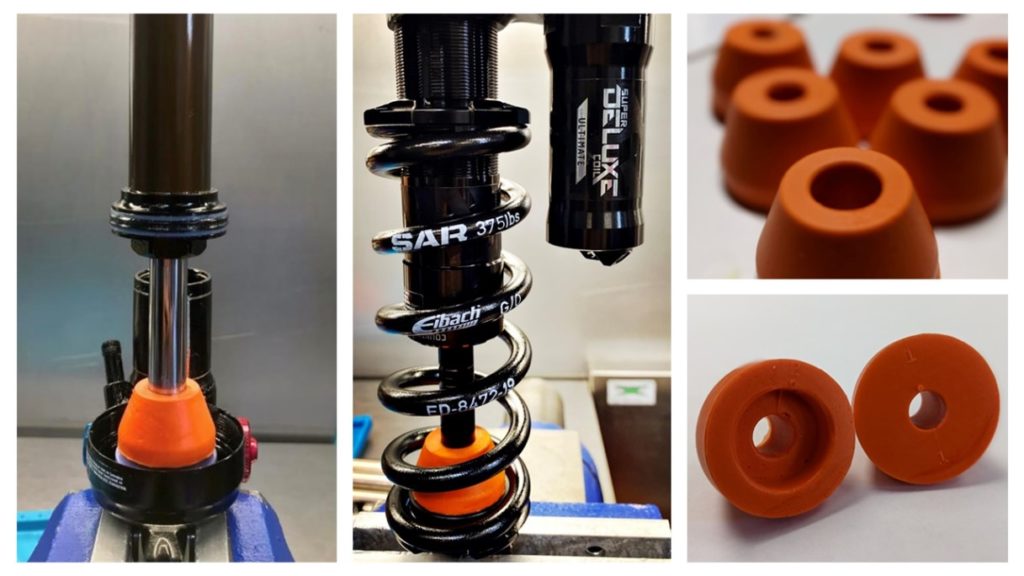

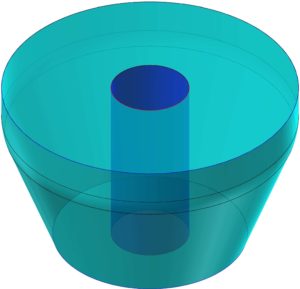

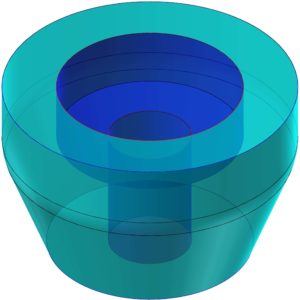

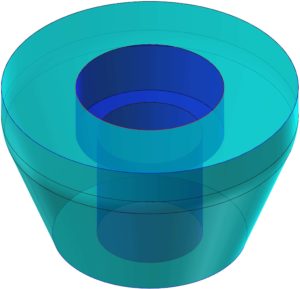

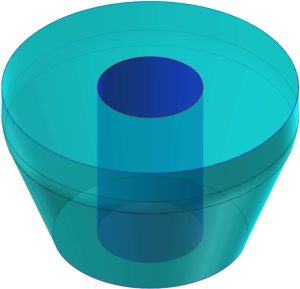

The one aspect of a mountain bike shock that is often overlooked is the bump stop. In a lot of cases, some manufacturers use an O-ring in place of a traditional bump stop. The main reason to have a bump stop is that along with shock damping, they help to control and absorb the ending stroke of the shock.

In addition, they prevent the shock from having a harsh bottom out. The tapered design will help ease into the ending stroke of the shock, so the rider doesn’t feel like they are “hitting a wall.”

Having multiple rate bump stops will help suspension tuners, like Fluid Focus, fine tune their customers’ suspension. Additionally, frame manufacturers then have options on the kinematics of the frame design, as well as the stroke of the shock when ordering their desired shocks from the suspension manufacturer.

Furthermore, the shock manufacturers will have potential alternative options to offer frame manufacturers.

Traditionally, bump stops have been used on coil shocks. One advantage to using these bump stops in air shocks, is that since they are taking up volume within the shock’s air can, Fluid Focus has been able to reduce and/or remove some of the volume spacers that riders have been relying on for so long. Also, in shocks with smaller strokes (40-55mm), these bump stops will give heavier riders more support through the shocks’ entire range.

Poly Labs & Fluid Focus: Supported Mountain Bike Shocks

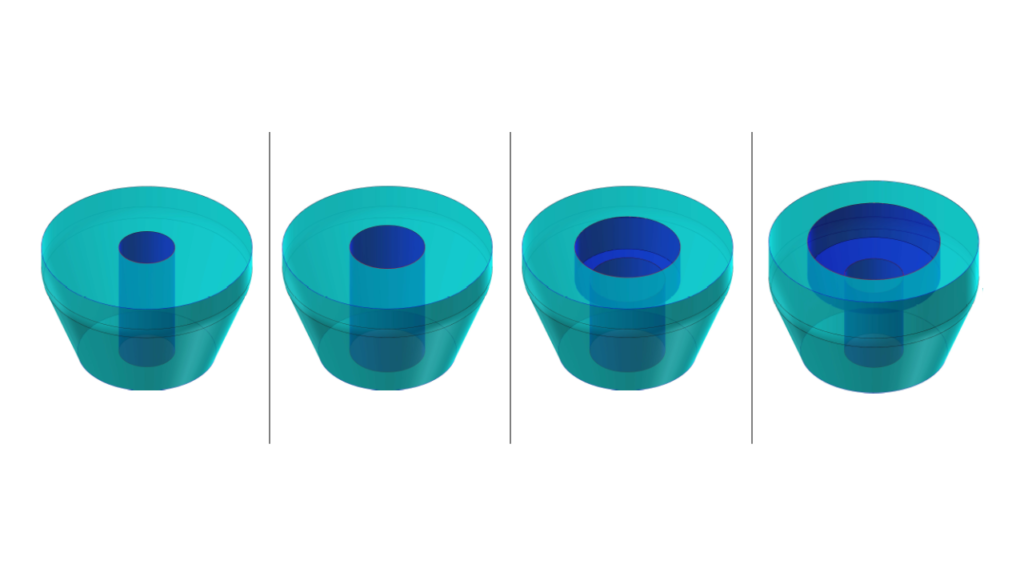

Currently, Fluid Focus and Poly Labs offer four different styles of bump stops (cavities 1-4), spanning a wide range of several common mountain bike shock OEMs and brands. Each size and design comes in two common durometers (35 and 45) to support various rider weights. Custom designs, sizes, and durometers are available upon request.

Our growing list of supported mountain bike shock systems includes:

Cavity 1

- Fox DPS

- Fox 2016-2020 Float X2, DHX2

- Older Fox RP23, CTD

- RockShox Monarch and Monarch Plus

- RockShox Deluxe

- Ohlins TTX Air

- DVO Topaz and Topaz 2

- CaneCreek Inline Air and Coil

- Cane Creek DBair and DBcoil

- Cane Creek Kitsuma Air and Coil

Cavity 2

- Fox 2021 + Float X2 and DHX2

- Ohlins TTX22m

Cavity 3

- Fox DHX (current)

Cavity 4

- RockShox Super Deluxe Coil / Air

- Fox Float X (current)

- Fox DHX, RC2, RC4 (older)

- DVO Jade and Jade X

- Fox DPX2

- Marzocchi Bomber CR

- Fox Float X (older)

About Fluid Focus

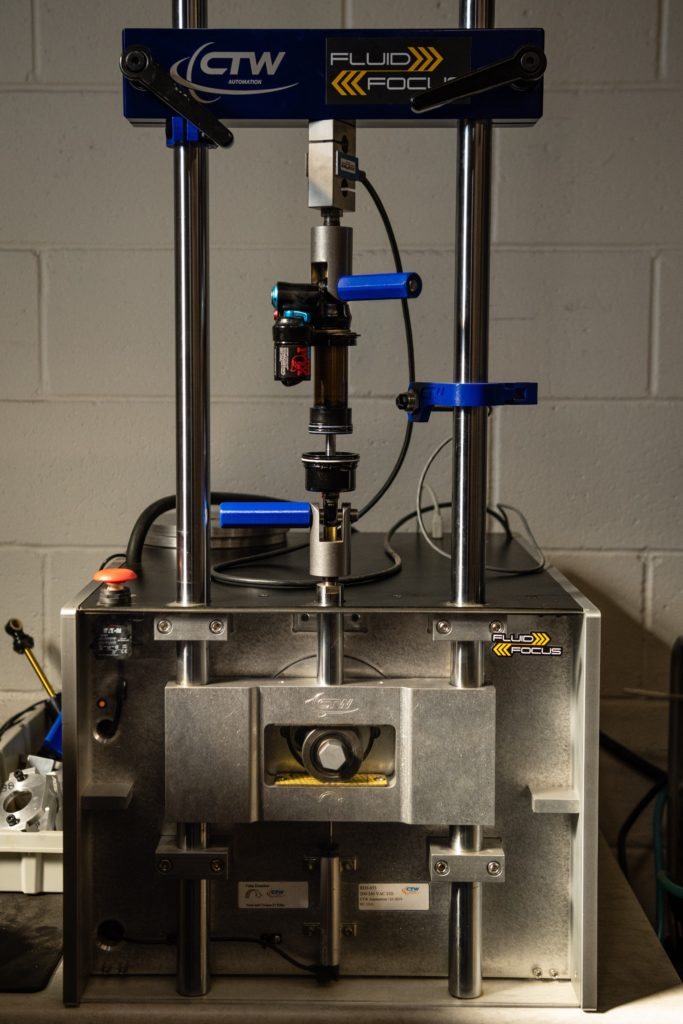

Fluid Focus specializes in offering factory level, professional, and personalized suspension tuning, repair, and service. Fluid Focus has years of extensive suspension experience which includes factory race team duties. Their full-service mountain bike suspension service center is in San Marcos, California, USA. Fluid Focus qualifications include: United Bicycle Institute Certifications, FOX master tech certified, and have factory race team suspension experience. Fluid Focus utilizes a state-of-the-art suspension dyno for all custom fork and shock tunings.

About Poly Labs

Poly Labs is an innovative polyurethane, TPU, TPE, and TPR materials and components manufacturing company headquartered in Lewiston, Maine, USA. Their main areas of expertise include the development, engineering, molding, and production of highly-engineered PU foam systems, as well as injection molded TPU, TPE, and TPR components. The finished goods made at Poly Labs reach several applications and end users, including: outdoor and recreation, footwear, impact protection, defense, medical, industrial, and consumer goods.

To learn more about the partnership between Poly Labs & Fluid Focus, please contact: