Integral skin foam offers a more high-density and thicker dense outer skin which is ideal for a number of applications including arm rests. The internal, underlying foam core is formulated with a lower density. Usually, Poly Labs integral skin foam has a density between 0.25 and 0.40 g/cm³. The hardness of the material can vary with formulation and density.

Our Microcellular and Integral Skin Foams

Microcellular Polyurethane Foam has a fine cellular structure throughout the foam. While the outer skin layer is not as well defined as an integral skin foam, microcellular PU foam generally has a density between 0.25 and 0.65 grams per cubic centimeter. Poly Labs currently offers numerous different Microcellular Foams based on the application and end market. The technical specifications for each vary, depending upon application, formula and desired properties. Several of our microcellular foams can be formulated to offer integral skin outer layers.

Microcellular PU Medium Density U-94 Foam

U-94 is a medium density, medium hardness foam for applications where a densified skin offers great mechanical properties. Poly Labs recommends in-molding, coating and/or post painting U-94 to protect lighter colors from UV degradation. Typically, the properties of U-94 are as follows:

| Density | 0.42 to 0.63 g/cm³ |

| Hardness, Shore A | 45 – 65 |

| Tensile Strength | 475 psi |

| Elongation | 435% |

| Die C Tear | 70 pli |

| Ross Flex, cycles to failure @ -20°F | > 100,000 |

| Abrasion Resistance, Taber, mg loss per 1,000 cycles | < 200 |

| Skin Tear | 28 – 45 pli |

| Foam Tear | 20 – 26 pli |

| Linear Shrinkage | 1.25 – 1.50 % |

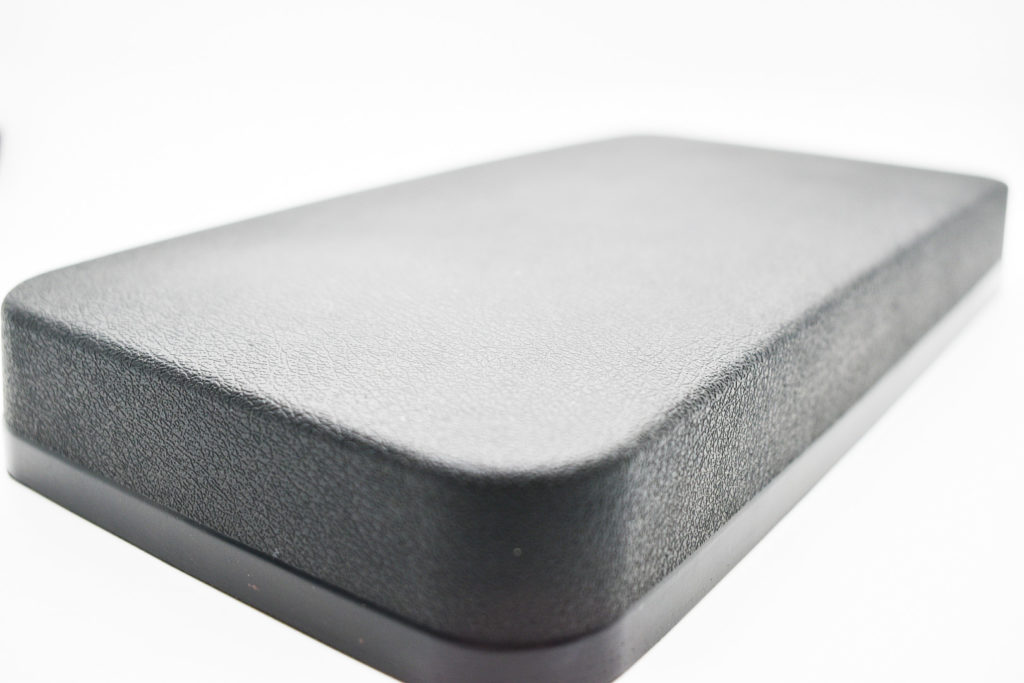

Integral Skin and Medium Density Microcellular U-92 Foam

U-92 Microcellular PUR foam is a medium density Integral skin foam that offers a thicker outer skin which is ideal for a number of applications including arm rests. The internal, underlying foam core is formulated with a lower density. Usually, Poly Labs integral skin foam has a density between 0.25 and 0.40 g/cm³. The hardness of the material can vary with formulation and density. foam for applications in which soft-padding is desired. Typical applications for U-92 polyurethane foam include:

- Furniture armrests

- Automotive armrests

- Recoil pads for rifles and shotguns (right)

- Recreational padding

- Head rests

- Back rests

- Insoles

- Other soft padding products

Poly Labs advises U-92 PU Foam be in-molded, coated, or post-painted to protect light colors from ultraviolet light degradation. The properties of our medium density, U-92 foam are as follows:

| Density | 0.25 to 0.35 g/cm³ |

| Hardness, Shore OO | 65 – 75 |

| Tensile Strength | 300 psi |

| Elongation | 225% |

| Die C Tear | 29 pli |

| Abrasion Resistance, Taber, mg loss per 1,000 cycles | < 200 |

The Poly Labs team also manufactured fatigue mats molded in U-92 foam to alleviate foot discomfort during long periods of standing.

Durable Polyurethane (PU) W-02 Foam for Footwear

W-02 is an extremely durable polyurethane designed specifically for footwear outsole applications. Typically, this polyurethane is molded to form rugged outsoles for work boots and casual shoes.

| Density | 0.55 to 0.65 g/cm³ |

| Tensile Strength | 580 – 720 psi |

| Elongation | 400 – 450% |

| Die C Tear | 85 – 115 pli |

| Abrasion Resistance, Taber, mg loss per 1,000 cycles | < 75 |

| Abrasion Resistance, DIN 53516, mm³ loss | < 200 |

| Foam Tear | 20 – 25 pli |

| Ross Flex, cycles to failure @ -20°F | > 100,000 |

| Oil Swell, ASTM #3 | < 15 % |

| Fuel B | 37 % |

| Fuel F, Diesel | 13 % |

| Oil Resistancy | > 250,000 |

| Slip Resistance, James Test | |

| Wet | 0.89 |

| Dry | 1.06 |

| Two Hole Stitch Tear | 288 (lbs. per inch) |

| Hardness, Shore A | 60 – 75 |

| Linear Shrinkage | 0.50 % |

PU Foam W-62 for Midsoles

W-62 is a medium density polyurethane foam, engineered specifically for midsole applications. The midsole is one of the most critical parts of the shoe sole, as it is designed to provide cushioning, support and shock absorption.

| Density | 0.35 | 0.4 | 0.5 |

| Tensile Strength | 262 psi | 305 psi | 352 psi |

| Elongation | 383 % | 470 % | 530 % |

| Die C Tear | 39.5 % | 45 % | 56% |

| Taber Abrasion | < 100 mg (loss per 1,000 cycles) | ||

| Foam Tear | 16.0 pli | ||

| Ross Flex | > 100,000 (cycles to failure @ -20°F) | ||

| Hardness (Shore A) | 30.0 | ||

| Linear Shrinkage (%) | 0.9 |

PU Foam U-46 for Insoles and Other Padding

U-46 is a medium density foam for footwear insoles applications and other padding. U-46 has excellent rebound properties for shock absorption. This microcellular foam is able to be co-molded on fabric or plastazote.

| Density | 0.33 g/cm³ |

| Hardness, Shore OO (10sec) | 60 – 65 |

| Tensile Strength | 162 psi |

| Elongation | 178% |

| Die C Tear | 15 pli |

| Trouser Tear (p/l) | 9.0 |

| Compression Set, 50 % at 77°F | |

| Of original thickness, (%) | < 1 |

| Compression Force Deflection, psi | |

| 25% Compression | 13 |

| 50% Compression | 23.5 |

For all of your microcellular and integral skin polyurethane foam needs, please contact our sales team.